Maintainance, Monitoring and Repair

The maintenance of a biogas plant comprises all work which is necessary to guarantee

trouble-free operation and a long working life of the plant. Repair reacts to breakdowns of the

biogas system. Maintenance services should be carried out by the manager or main operator

of the biogas plant or a well-trained biogas technician. One has to bear in mind that

measurements indicating problems may be wrong. All doubtful measurements have to be

verified. Often, one symptom has a variety of possible reasons.

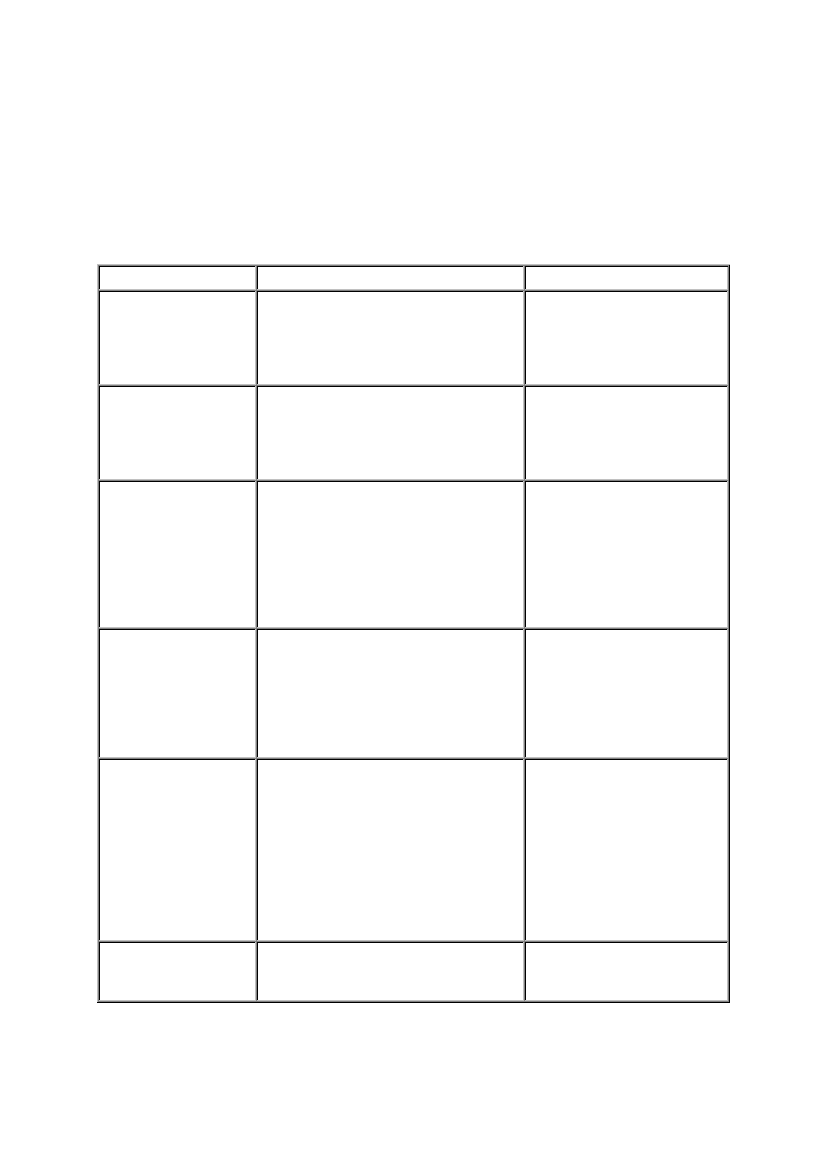

Daily maintenance work

Control

gas pressure

substrate

temperature (heated

plants)

(bacteria are very

sensitive to

temperature

extremes and

fluctuations);

gas production

strong sludge odor

Mistakes

Removal

gas pressure too high;

(gas pressure rises, if gas

consumption is lower than the

production and if the gas storage is

full)

The pressure relief valve

malfunctions - it should be

cleaned or renewed;

gas pressure too low;

leakage in gas conducting

(gas pressure falls, if the consumption parts: find out the leakage

(including leakage!) is higher than the and seal;

production and if the gas storage is gas production has fallen:

empty);

check the sludge’s quality;

temperature too high;

defective heating control

system. Check control

system and repair or

exchange part(s)

concerned;

temperature too low;

gas production clearly under normal

levels;

plant is overloaded or

fermenting conditions are sub-

optimal;

defective heating control

system. Check control

system and other concerned

part(s), repair or exchange;

sediment layer on the

heating surface: remove

layer;

biological reasons:

temperature, substrate,

antibiotics, change of pH-

value;

leakage in digester or piping

system; blocked gas pipes

due to water or alien

elements;

identify problem and act

accordingly;

reduce substrate intake;

correct pH-value with

adequate means;

72